Name: Alice Wu

Fax: +86-0319-8110111

Mobile: +86-13703192232

Mail: info@rf-tungstencarbide.com

Add: NO.22,Lijiang Street,Qinghe County,Xingtai,Hebei,China(Mainland)

Whatsapp / wechat / skype:

+86-13703192232

+86-18631903118

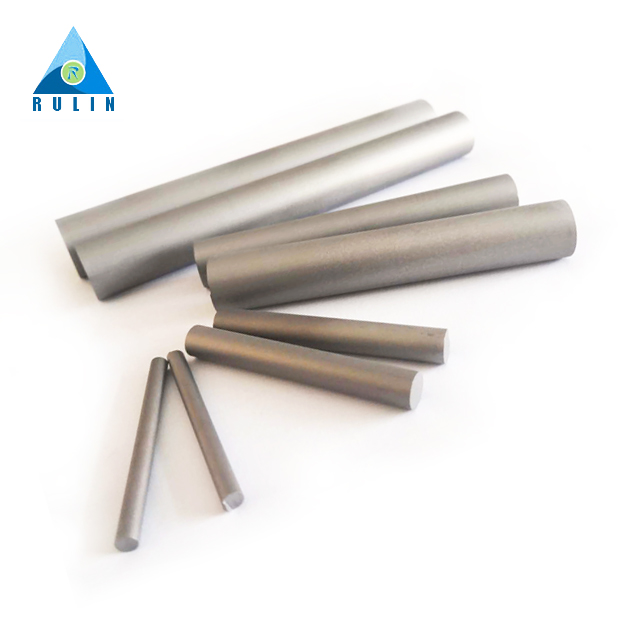

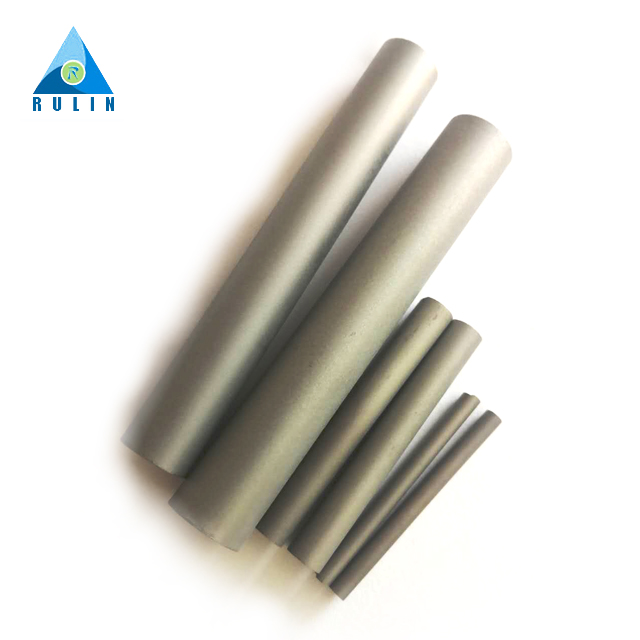

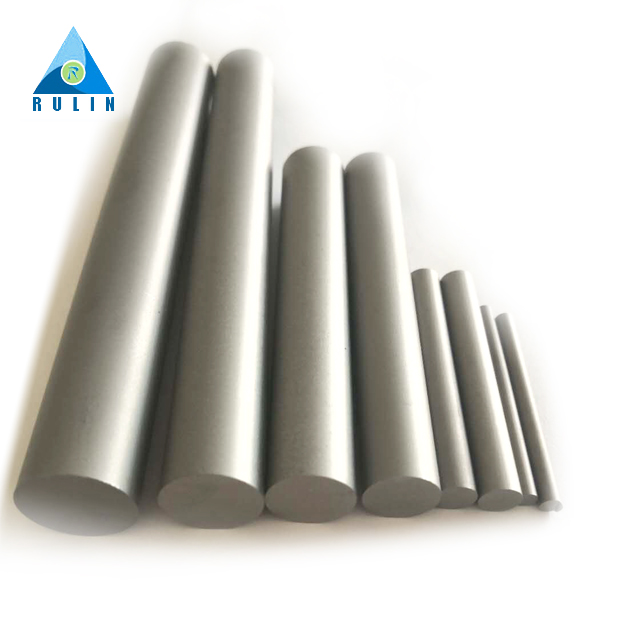

Carbide round bars, also known as tungsten steel bars, are simply tungsten steel bars or carbide bars. Cemented carbide is a composite material composed of a refractory metal compound (hard phase) and a binder metal (bonded phase) produced by powder metallurgy. Carbide, also known as tungsten steel, is relatively different in local terms.

stable perdomance

easy welding

Wear resistance,

Impact resistance

Name

Tungsten carbid Rod

Product Method

Power Metallurgy

Another name

Tungsten steel

Property

cemented carbide cutting tools

Characterisitic

Range of application

Papermaking packaging ,printing, non-ferrous matel processing

Cemented carbide (WC) is an inorganic compound containing equal amounts of tungsten and carbon atoms. In its most basic form, it is a subtle gray powder, but it can be used in industrial machinery, tools, abrasives, and shapes used. Cemented carbides have three times the carbon content of steel and are denser than steel and titanium. Its hardness is comparable to that of diamond and can only be ground into a hard alloy and polished with cubic boron nitride abrasive.

Carbide rods are a new technology and new materials. Mainly used in the manufacture of metal cutting tools, wood, plastics, hardness and wear resistance, corrosion resistance products, etc.

Grade:YG6 YG8 K20 K30 yg10x yg11c P20 P30 ...

Carbide rods are carbide cutting tools for different rough grinding parameters, cutting materials and non-metallic materials. At the same time, carbide rods can also be applied to conventional automatic, semi-automatic lathes and the like.

The main process flow includes milling → formulation according to the application requirements → wet grinding → mixing → crushing → drying → sieving → adding molding agent → drying again → sieving to make the mixture → granulation → pressing → forming → low pressure Sintering → Forming (blank) → Cylindrical grinding (the blank does not have this process) → Inspection size → Packaging → Storage.

Please feel free to contact me for any questions

Whatsapp:0086 13703192232/ 0086 18631903118